Capabilities

With industry-leading manufacturing, engineering, fabrication, and welding, plus trusted testing and inspections, we build with your long-term success as our top priority.

Manufacturing

Excellence starts with proven processes and strict quality control.

- Compliant to ISO/TS 16949, ISO 9001, Core Tools, APQP, and Control Plan

- Equipped to perform all measurement inspections using calibrated hand measurement tools and Coordinate Measurement Machine (CMM)

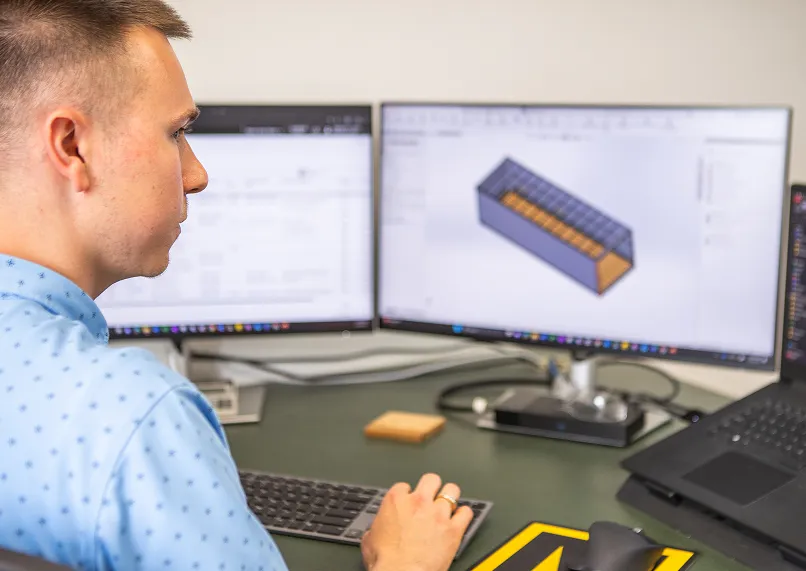

Engineering

Our dedicated engineering teams provide custom bodies that adhere to the strictest specifications.

Custom designs, engineering to prints, or reverse engineering

Rapid prototyping certifications including ISO 9001-2015 and Six Sigma Black Belt

Fabrication

We leverage state-of-the-art equipment and technologies to build you stronger, more reliable structures—and respond with agility when customization is needed.

- Tougher box frames with added structural support

- Aluminum extrusions with superior dimensional reliability

welding

Get precision workmanship and rugged construction that hold up under pressure—because your project deserves proven durability and reliability.

Testing & Inspections

Demonstrating Quality Through Testing and Inspections Is a Must, Not a Nice-To-Have

Internal testing

- Cycle and fatigue

- Adhesive bond strength

- FEA analysis

- Water testing

External testing

- ECE-29 tests on all cabs

- Seatbelt testing

- Corrosion testing

- Pump testing

U.S. Patents Marion Body Works Holds