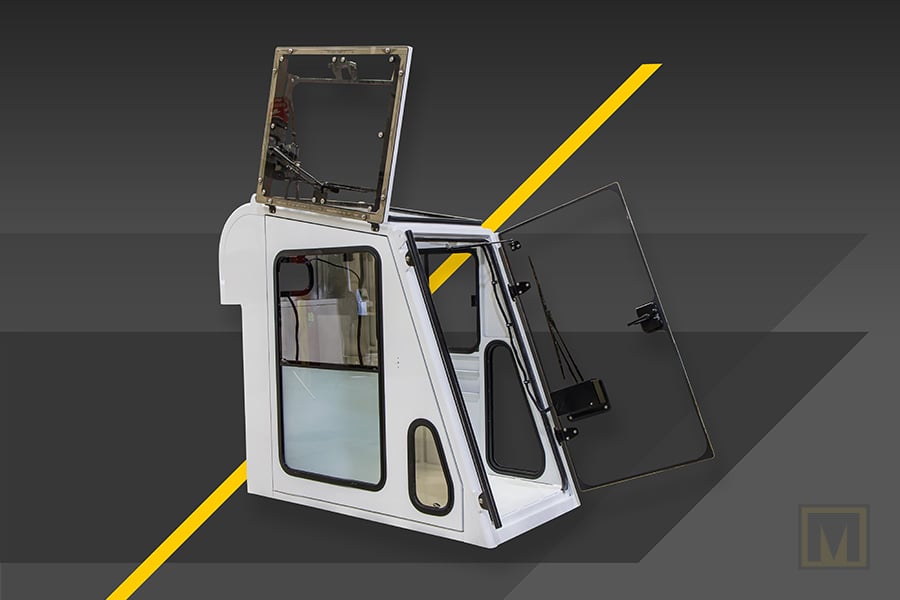

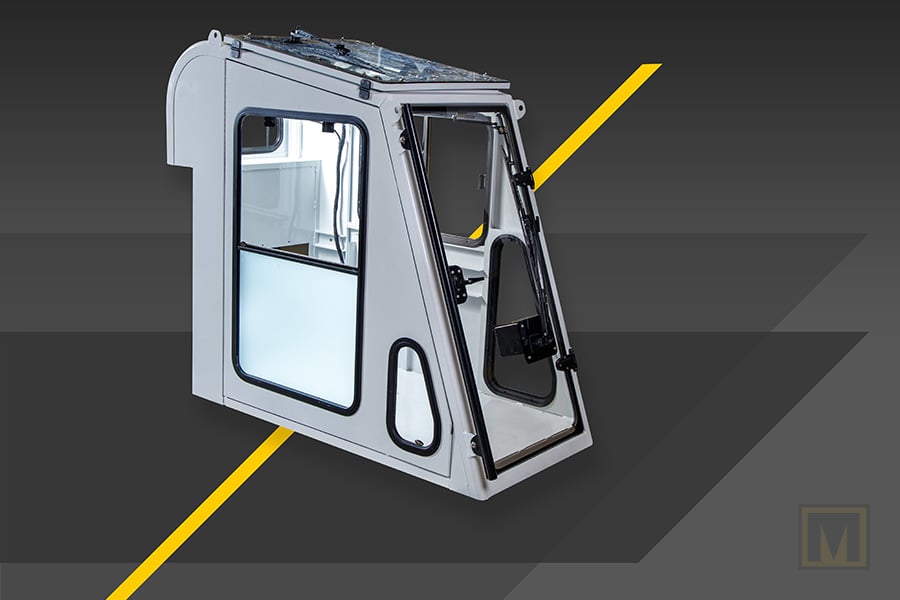

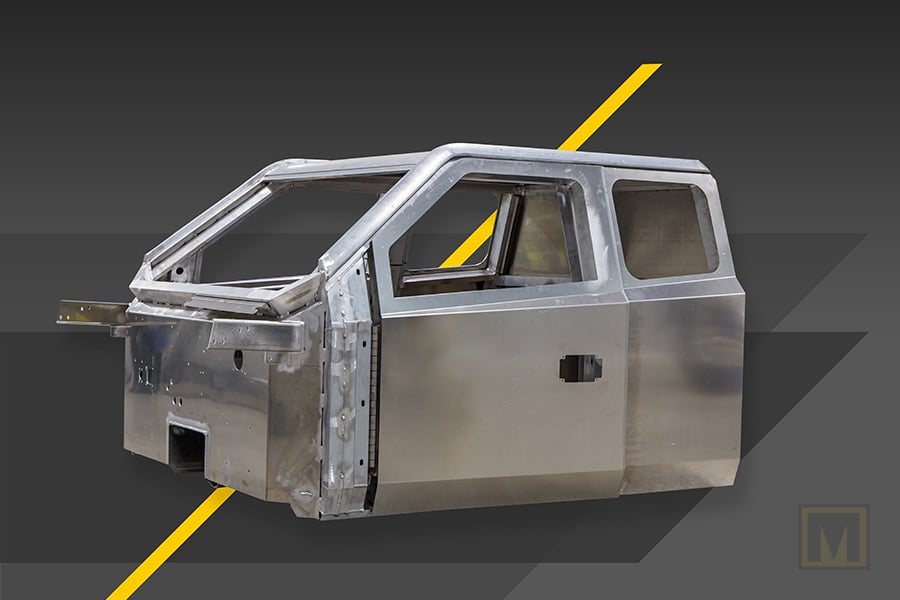

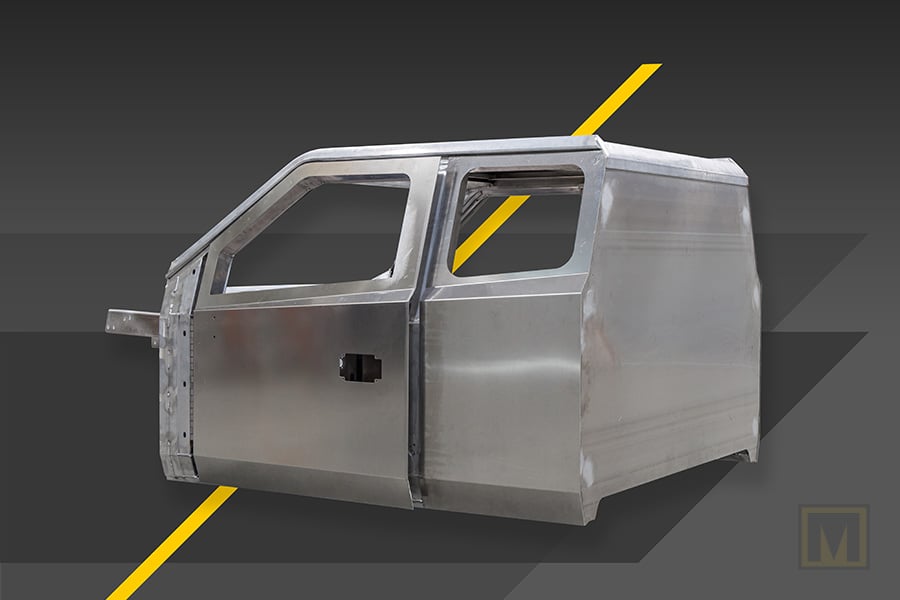

We deliver true custom cabs and enclosures.

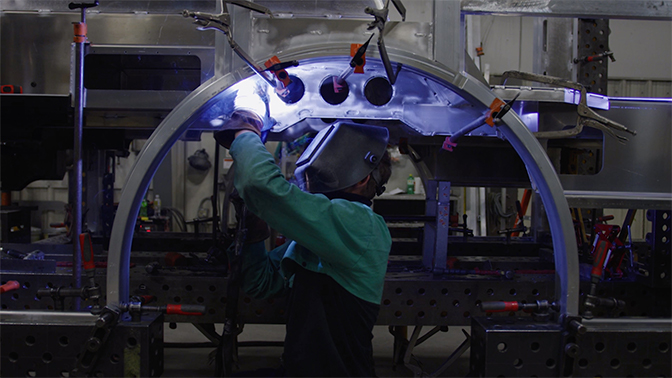

Marion engineers work with OEMs to introduce new product lines or produce products for niche markets. With an integrated design approach, we match current OEM designs to drive parts commonality and form and fit down the assembly line. Our cabs also come with a 10-year structural warranty.