As you’re probably aware, pumpers are the most common type of apparatus used in today’s fire service. The pumper is often the go-to apparatus whenever a department is called to a fire, as the pumper’s main purpose is to provide personnel with sufficient water, equipment, and other tools used to sustain an initial attack on a fire. These trucks are known to do a little bit of everything out on the fireground, but they won’t be able to accomplish much without the proper water tank or pump capabilities. Without a pump or water tank, a pumper is just a truck that transports people and gear to and from the scene. All other components of the apparatus are effectively useless if these two features can’t perform adequately, and departments should be extremely thorough when selecting a tank design and choosing a pump.

To ensure your pumper will have the right tank and pump for any situation, here are 6 things you should consider before deciding on a water tank and pump for your apparatus:

FIRE TRUCK WATER TANK CAPACITY

The minimum water tank size for a pumper is 300 gallons, with sizes typically ranging up to 1,250-gallon capacities on standard, single-axle-style pumpers. The perfect water tank size will vary from department to department, and is dictated by several factors. Make sure you consider the following factors before settling on a water tank design for your pumper.

HOSEBED HEIGHTS IMPACT WATER TANK SIZE

While there are several factors that will determine the height of your hosebed (e.g., built-in ladders, full vs. split depth storage compartments, etc.), keep in mind that larger water tanks require more space, and a taller hosebed provides apparatus builders with more vertical space to accommodate tanks. If you require a shorter hosebed, however, builders will have to be a little more creative with the tank design and placement given the limited space. This situation might require a longer apparatus or a crosslay hosebed design. Learn how Marion combats high hosebed problems.

Local Water Sources

How many fire hydrants are in your response area? How many tenders and personnel are available at any given time? If you don’t have many water sources to rely on, you’ll need a bigger tank to provide a sufficient water source for your initial attack. Calculate the average distance and response times from water sources in your area to help give you a better idea of what size tank you’ll need.

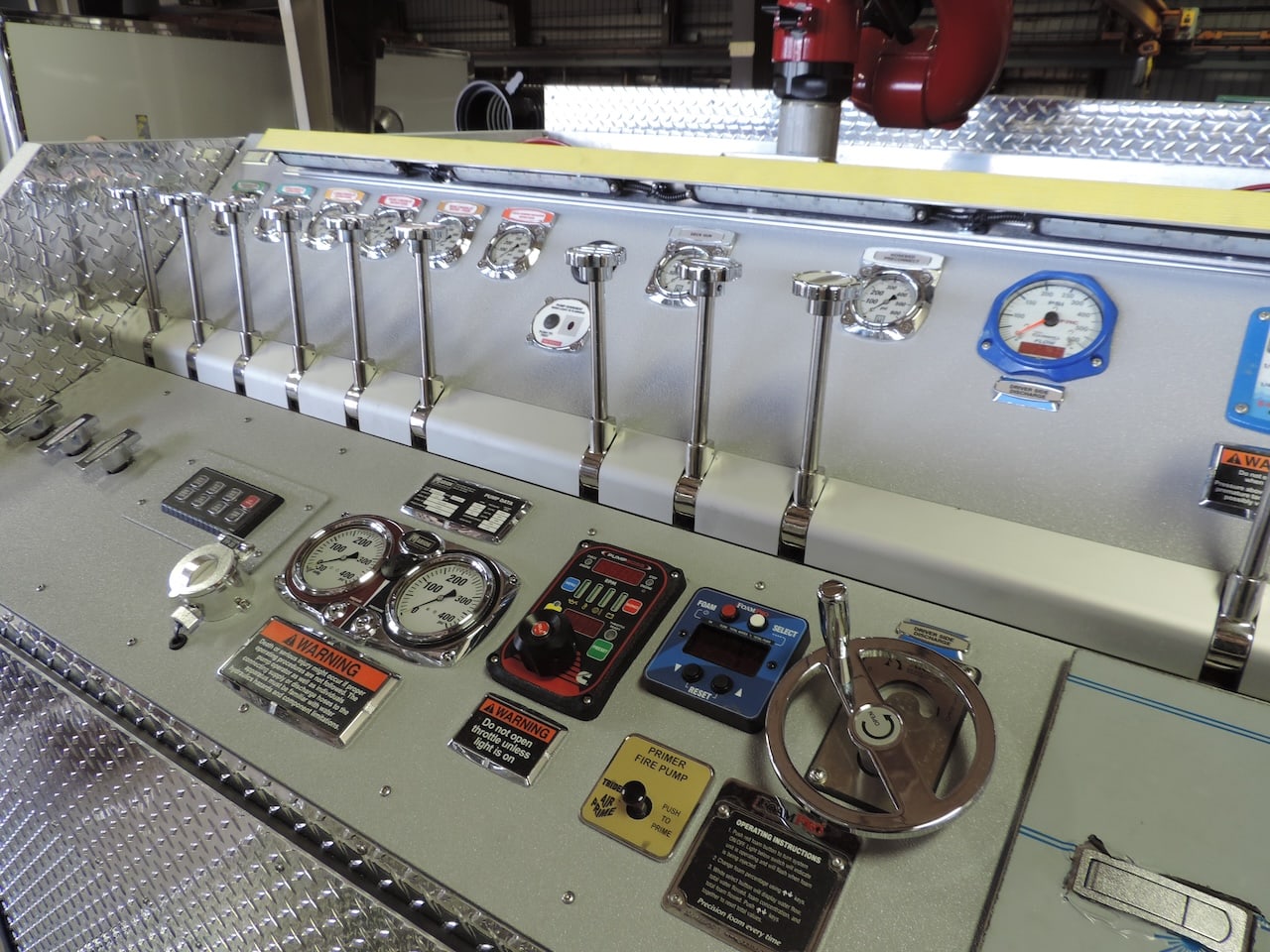

PUMPS

Fire pumps on today’s pumpers typically range from 750- to 2,000-gpm flow capacity. The bigger the pump, the more water you’ll be able to put on the fire faster, but there are a number of factors you need to consider before making a decision, including:

Minimum GPM Requirements Set by ISO

When it comes to choosing a pump for your fire apparatus, the Insurance Services Office (ISO) will have already set a minimum gpm requirement for your community, based on building construction, size, distance from other structures, and other factors. Fire departments can exceed this number as they see fit, but they must meet the minimum.

Single vs. Two Stage PUMPS

More than 90% of today’s pumpers are being built with single stage pumps due to the simplicity of the design and operation, as well the reduced weight and cost. However, if your city features a number of high-rise buildings, you may want to purchase a two-stage pump to ensure you have the proper water pressure.

Apparatus Cost

Though the pump is a necessary feature on your apparatus, and you’ll have to pay at least a certain amount to meet your ISO requirements, it’s important to keep in mind that pumps with a higher gpm rating usually require more valves on your apparatus – which will increase the purchase price. Sit down with your APC (Apparatus Purchasing Committee) to figure out exactly how much you can afford to spend on your pump and its components, and make sure you keep everything within your limits.

Apparatus Limitations

Just like with your water tank, your apparatus chassis, design, and engine horsepower will play a key role in determining what size pump you can use. Bigger pumps mean more size and weight, though most apparatus are able to handle up to a 1,750-gpm pump. You’ll also need to make sure your engine HP performance curve is capable of running the components you desire.

With your pumper often being the first apparatus on the scene, you want to make sure you can start getting water on the fire as quickly as possible when you arrive. In order to do that, it all starts by having the perfect water tank and pump combo for your apparatus.

To learn more about the different pumper options Marion offers, including our new RPM apparatus, talk to your nearest Marion Dealer or contact us directly at (715) 754-5261.