Make the Move: Marion's 6 Types of Apparatus

Make the Move: Marion's 6 Types of Apparatus

Make the Move: Marion's 6 Types of Apparatus

The Journey To Your Next Truck - Part 4

Building Your Truck

In just ten working days, your truck has been transformed from a 2D drawing to a complete set of 3D engineering renderings for every system, laser cut part and precision weld. The Chassis and engine have been ordered, along with the all the materials and vendor supplied components. In the next 12 weeks, electronic data will become fully functional piece of firefighting apparatus awaiting your inspection in our state-of-the-art delivery bays.

“Marion is different,” said Ross Fischer, Production Manager for Fire & Emergency, “It’s important to be open to ideas on both sides. We will listen to you, and if you’re willing to listen to us, together we will get your truck to work.” Of course, before we hand you the keys, our highly skilled fabrication team will to have turn raw materials and certified components into a fire truck.

While we’re building your truck we are also building Marion’s reputation for quality that stretches back 113 years. One key element is our continuity in personnel with employees like electrician Rick Hidde who has been with us since 1968 and final assembly lead Pete Pockat who has been at Marion for 30 years. “It means so much to have guys like Rick and Pete,” said Fischer. “They are our history, they’ve seen it and done it. Every truck is different, and the younger guys might not have seen a particular application or adaptation. Everyone knows to go ask Pete and Rick. We’ve had customers call with questions about trucks we built years ago, somehow they remember it.”

Production Manager Fischer will convene an initial meeting with engineering and each of the four build team leaders. They will review the engineering specs and give input based on their fields of expertise. The approved plans will be sent to computer terminals on the shop floor in the Frame Up, Plumbing & Chassis Modification, Electrical and Final Assembly departments. Over the next three months, more than 30 highly skilled craftsmen will build your truck practically from the ground up. Their orchestrated movements will circle around the truck chassis, adding parts and assemblies until its bare bones become the customized unit you’ve ordered.

Body panels and supporting structural tubing will be laser cut from military grade aluminum stock in the Fabrication department and Frame Up will weld and construct the body. Simultaneously, the Plumbing department builds and plumbs the pump module and electricians wire it once the completed module is set in place on the chassis. When the body comes back from the paint department and is set on the chassis the doors, lights and diamond plate are installed. The Final Assembly department will then install water tanks, generators, and other components as specified.

At this point, the nearly completed truck enters the testing phase where the pumping system is filled with water, fired up and checked for leaks. Upon in-house approval by the Production Manager and Department Leads, your truck will be submitted for third party testing under full power. We will then finish off the tags and covers, trimming out the vehicle and getting it ready for inspection first by the team Leads to make sure it meets the engineering specs, then by the sales team for our final approval. When, and only when, the truck passes every one of our in-house quality control standards, we’ll invite you to do the same in our state-of-the-art delivery bay. Marion has been delivering on promises for 113 years, what would you like to order?

The Journey To Your Next Truck - Part 3

Engineering Your Truck

Your journey to a new truck has progressed from a community need, into a concept, then moved through budget meetings and fundraisers. Your team has met with sale professionals and maybe even visited manufacturers, reviewing diagrams, renderings, and quotes. You have finally agreed on a design and are ready to place your order. It's time to sign on the line and get that truck built! With most manufacturers, you’d be right. Marion isn’t most manufacturers, we’re going to go over the entire project again with our engineering team to validate the designs and preflight the build. Adding this extra step eliminates minor mistakes before they become big production headaches, keeping your build on time and on budget.

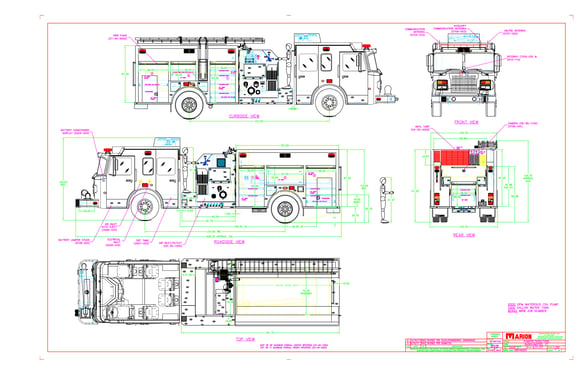

Marion’s Engineering Department becomes involved in earnest upon your acceptance of the truck bid. Prior to final acceptance, your Technical Sales & Contact Administrator (TSCA) will meet with representatives from our engineering team to verify the 2D Sales drawings, check for errors and come up with the final submittal. You and your team will meet with your TSCA, and our Engineering team to critique any changes that have been made to the truck. Upon your approval, the designs are released to engineering. Your TSCA will then meet with our full team of electrical, plumbing and mechanical engineers to bring your vehicle to life.

The Body Department will convert the 2D sales drawings to the 3D engineering renderings for fabrication of the truck, while the electrical engineers make CAD drawings for the wiring harness and plumbers design the piping plan. The engineering team will work together to develop interconnected systems for control panels and consoles, preflighting layouts and verifying components. This will include going over the order item by item and verifying special items. They will generate engineering drawings and/or specification sheets for any special order parts or components that are included, create diagrams for special options and create custom harness prints for any options that require them. Chassis modifications and equipment installations will be finalized and then reviewed by the entire team before placing orders for components and scheduling fabrication.

While it sounds like a monumental effort, Marion has finely tuned the process so that an approved submittal is transformed into a completed blueprint in just eight working days.

“We assist sales early on and provide support to the TSCA throughout the quoting and specifying process to achieve the cleanest spec possible,” said Josh Richling, Electrical Designer. “By getting involved early, we can work around potential problems before they become engineering nightmares.” Once the final prints are approved, the purchasing department and fabrication team will create the part delivery and manufacturing schedules. The engineering team, along with the TSCA will continue to support the fabrication team through every weld, rivet, and coat of paint.

This streamlined system has been perfected over years of dedication and craftsmanship.

The Journey To Your Next Truck - Part 2

Specifying to Engineering

Once you’ve sent your specs and design parameters off to your chosen vendors, you can sit back and wait to review their final numbers, right? Probably not. In actuality, the specifying process has only just begun. You see, there are a great many options to consider and pathways to take to get to a finalized estimate. Again, it all comes down to budget limitations versus the capabilities you need and those you would like to have. This doesn’t mean you have to simply take what a manufacturer will give you for your dollar. You should have the opportunity for many reviews with your builders to achieve an optimum balance of cost to capability and also for future needs and adaptations.

“At Marion, we pride ourselves in being able to pre-plan for future upgrades,” said Rob Rosenau, Technical Sales & Contact Administrator. “An excellent example is a light tower, which is a very expensive option. To help you meet your budget, Marion can design the truck with all the necessary wiring and support elements in place at the time of delivery. When future funds become available to purchase the tower, we are able install the it quickly, with the shortest time out of service and smallest possible cost.” Because everything changes in the Fire Service, it is essential that your manufacturer plans ahead for new equipment that has to be stored on the rig. If your manufacturer is lining out items in your spec without offering ways to easily add them later, or only giving you enough room for today’s tools, you may be getting pushed into a cookie cutter design that fits their needs more than yours.

It is also important to know who you’ll be working with you on your project. Marion initially assigns a Technical Sales & Contact Administrator like Rob, who will be involved in every aspect of with your truck from design through building to service in the field. Yes, the guy who worked on your specs will be the guy you work with for upgrades down the road. Who else can say that? He will work with your local Dealer and two internal specialists on your primary estimate. This team will grow to up to 15 highly qualified engineers, electricians and plumbers who will review every weld, fitting and connection that has to be made. As the process continues, the team will expand to move the truck through manufacturing, paint and delivery. The constant through it all will be your TSCA. At Marion, we want you to be involved in every step of your truck’s process, and we believe the best way to do that is to give you one very skilled person to talk to, someone like Rob.

The Journey To Your Next Truck

Your Department has decided to go custom for their next truck. What next?

You’ve had all the meetings, worked out the budget and financing options and finally gotten the go-ahead to start specing out a new piece of custom apparatus. Now what? You may feel overwhelmed by the sheer number of manufacturers and reps willing (clamoring) to bid on your truck. We understand. We’ve put together a few simple guidelines to help you through the process of initial specification through RFQ.

First of all, understand the mission of the apparatus. This is a purchase that could be in your station for over 20 years and nobody wants their name pinned to failure. It sounds pretty obvious, but if you don’t have a clear vision for the truck, you can end up with a spec that leaves too much leeway to the competing manufacturers, forcing you to reconcile bids and go back to the drawing board. This can lead to some unfortunate delays and cost over-runs. Marion has built a number of very unique customs in our 112 year history, it is our specialty. Our Sales Reps will work with you to clearly define what you need up front so we can engineer a solution for your needs.

Next, be clear about your budget. You can only spend what you have been allotted. It is a simple fact of life, but that doesn’t mean you have to compromise quality for capability. Consider the fact that bigger is not always better, and you might be able to do more with less. Why pay for a 450 horsepower engine if you can accomplish the same goal with 375hp and advantageous gearing? Also think long-term about maintenance and warranty coverage. Marion reps have the experience to recommend successful solutions for overcoming most budgetary limitations, and Marion trucks have one of the most comprehensive warranties in the industry.

Most importantly, know your manufacturer. Ask if they’ve built a truck similar to your concept for a nearby department, and then ask if you can go see it. Ask if you can take it out for a test drive, you wouldn’t buy a car without driving it first, after all. Talk to their Chief about the design and build process, find out about maintenance and service needs. You can learn a lot about a manufacturer by reading through the service record for their trucks. If your rep is unwilling or unable to show you a comparable truck, you might want to look into a different brand.

Ultimately, you are going to spend a great deal of time, money and effort to take a truck from concept through delivery. It is a decision that can take up to 2 years to see through to fruition, and last for decades. You’re going to have to partner with a company who values your reputation as much as they do their own. We invite you to look at Marion, and join our 112 year tradition of quality.

The Marion Difference

Why Choose a Marion?

The old saying, “You are what you eat” is easily understood by nutritionalists, athletes and firefighters across the land. Simply put, to build a better body, you need to use better building blocks. Nowhere is this concept more prevalent than inside a Marion Fire Truck. Our Engineering team has taken the concept to heart, incorporating military-spec grade aluminum extrusions into every rig we build.

Why military-spec grade Aluminum? It has a tensile strength that is 91% stronger than 3003 sheet and 43% stronger than 5052 sheet. It is the proverbial “better building block” that we use as our foundation. Our engineers incorporate the superior properties of our aluminum stock into our apparatus designs to build a body and chassis system that is strong and light weight, while maintaining its structural integrity. It is so essential to our process that we purchase more than 1 million pounds of it each year.

While other manufacturers may form, bend and weld their support columns and bracing components piece by piece, we source our virgin aluminum extrusions from America’s best mills. This means that the tolerances we specify are certified on every lot with absolutely no variance. The closed-profile form of the structural extrusions provides excellent fit and finish during manufacturing and throughout the lifespan of the apparatus. They are cut to length, drilled, notched and milled on advanced CNC machinery with the tightest tolerances in the industry. Marion body panels are CNC laser cut from heavy-gauge aluminum plate stock with all secondary operations performed on our in-house equipment.

If you believe its what’s on the inside that counts, count on Marion.

Read More

Make Your Move to Marion

Get to Know Marion

Marion builds custom fire apparatus in the Northern Wisconsin town whose name we share. We are a 112 year-old family owned and operated business and count, in our extended family, a dedicated group of 270+ employees including: engineers, electricians, welders, fabricators, painters, service, sales and support professionals. The Marion family also includes every Department that we’ve ever built a truck for, and every firefighter who rides to the scene in it, and it includes every community that we help to protect.

A Marion truck is custom built from the ground up, from the highest quality components to your exact specifications. We have an open communication philosophy that runs through our entire manufacturing process, from the initial design consultations to your final inspections in our climate controlled service bays. We do not push you to a cookie cutter design. You want a 2000 GPM pump? We’ll install it the brand you want. Need a 1,000 gallon capacity tank, we’ll spec the chassis and body to accommodate it. Need a low hose bed, or extra storage for lifting bags and cribbing? Our engineers will design an answer. We will work with you to design and build the best rescue, pumper, tanker, aerial or hybrid rescue/pumper to serve your community.

We build trucks that are designed to last using extruded aluminum with precise laser cut edges and welded seams. We incorporate advanced manufacturing techniques with the latest engineering software and a tradition of quality stretching back to 1905. We build relationships by listening to you, our customer, and delivering on our promises.

What can we build for you?

Read More

Rescue Pumper or Heavy Rescue? How to Decide Which Is Best for You

While rescue pumpers have become very popular in the Fire & Emergency industry, many departments are questioning whether this is the best choice for them or if a heavy rescue is a better fit. There are pros and cons, of course, to each, so taking time to think through how each aligns with your department’s needs is critical before making an investment in either direction. Here are a few things to consider when identifying the best vehicle for your fleet:

Read More

Low Hosebed Fire Apparatus — Ideas, Options, and Considerations

The last time we talked about hosebeds, we explained how we design our apparatus to overcome the problems associated with high hosebeds. To make things easier for firefighters, we use ergonomic ladders, built-in steps, walkways, and other features to make high hosebeds safer and more accessible.

Read More

Choosing the Best Lighting Options for Your Fire Apparatus

Before most departments even start talking with an apparatus manufacturer or budgeting their new truck, there are often several features and specifications that are considered “must-haves” for the new rig. Rural departments interested in buying a new Tanker, for example, might know that a 3,500-gallon tank is the minimum required size to meet their operating needs for their area.

That being said, when it comes to the different lighting options for today’s apparatus, many departments are happy to just settle for whatever meets the NFPA 1901 minimum without exploring other options. This is because it can be difficult to understand all the capacities and options available, as well as understanding the NFPA standard.

Read More

6 Things to Keep in Mind When Specifying Your Next Rural Apparatus

While there are many notable differences between urban and rural fire departments, one of the most significant is the resources required. Take the availability of fire hydrants, for example. When a department is responding in rural environments outside the support area of hydrants, their tactics change drastically without having a reliable water source.

Read More

12 Paint & Chrome Maintenance Tips for Maximizing Apparatus Health and Appearance

Have you ever thought about why firefighters pay so much attention to cleaning and polishing their trucks? Apart from making sure they look good, have you ever wondered why they have to do so often? In reality, it’s about much more than just making the truck look shiny and new.

Read More

Fire Apparatus Front Bumper Configurations — Ideas and Options

With today’s fire departments looking for more storage space on their apparatus, front bumper extensions are becoming common on all apparatus types. Whether it’s a Rescue, a Pumper, a Rescue Pumper, or even an Aerial, front bumpers can be mounted on just about any apparatus these days, and they do much more than simply provide a place for your siren.

Read More

10 Tips for Laying Out a Walk-Around Rescue

Though walk-in Rescues have long been the preferred style by many fire departments, fire apparatus manufacturers have seen an increase in walk-around Rescue orders over the past several years. As fire departments are being asked to respond to more unique and specific emergencies that require more equipment than just for structural firefighting, they need vehicles that can carry this extra gear, and walk-around Rescues provide significantly more compartment storage space than walk-ins.

A new walk-around Rescue is a great opportunity to firm up your mission plan and have your tools combat-ready. To help you do just that, here are a few tricks, tips, and things to think about when laying out your next walk-around rescue.

Read More

7 Technology Upgrades That Improve Fire Apparatus Operations and Outdated Practices

Let’s face it: technology is evolving fast and changing the ways we operate in almost every facet of our life.

New technologies are drastically changing the way firefighters approach emergencies and design their fire apparatus, with many of these changes helping firefighters save more lives and work more efficiently. That being said, with any change comes apprehension and uncertainty, and the fire service has certainly built a reputation for being “traditional.” It’s not always easy to convince a veteran firefighter of new methods, but it’s much easier after careful consideration and discussion as to how it truly enhances the operation of your apparatus.

Read More

Buying a Pumper: 6 Considerations When Choosing a Water Tank and Pump

As you’re probably aware, pumpers are the most common type of apparatus used in today’s fire service. The pumper is often the go-to apparatus whenever a department is called to a fire, as the pumper’s main purpose is to provide personnel with sufficient water, equipment, and other tools used to sustain an initial attack on a fire. These trucks are known to do a little bit of everything out on the fireground, but they won’t be able to accomplish much without the proper water tank or pump capabilities. Without a pump or water tank, a pumper is just a truck that transports people and gear to and from the scene. All other components of the apparatus are effectively useless if these two features can’t perform adequately, and departments should be extremely thorough when selecting a tank design and choosing a pump.

Read More

Consolidated Construction and Marion Body Works Announce Expansion Project

Officials of Marion Body Works, Inc. announce that they have recently signed an agreement with Consolidated Construction Co., Inc. to build a new headquarters and expand an existing manufacturing facility at their 211 W. Ramsdell Street location in Marion, Wisconsin. Although actual site preparation and foundation work will commence immediately, an official groundbreaking ceremony date is set to take place on August 24, 2015 at 11:00 a.m., with officials from the City of Marion, Waupaca County, Marion Body Works and Consolidated Construction in attendance to turn the site’s dirt.

Read More

9 Questions Your Apparatus Purchasing Committee Needs to Answer Before Starting the Specification Process

If there’s one thing we know about the apparatus purchasing process, it’s this: no decisions are made without careful deliberation. From the start of the budgeting process all the way down to the final inspection, every single aspect of the new truck has to be given extra thought. When you spend more than $300,000 on something you plan on using for the next 15+ years, you can’t afford to make any mistakes – especially when your community depends it.

Read More

Apparatus Technologies Help Departments Do More With Less

Today, almost without exception, fire stations across the country are being asked to “do more with less” as a way to control expenses. Many departments have had to reduce their staff size and apparatus fleet, which leaves the rest of the department to take on more responsibility each time they answer a call. Consequently, departments have to be very careful about how they strategize their response plans and specify any new apparatus purchases.

Read More

Control Fire Apparatus Costs by Avoiding Frills Your Department Doesn’t Need

With the average new fire apparatus purchase costing well into the six-figure range, it’s easy to see why departments are very budget-conscious when investing in a new addition to their fleet. The price difference between a fully loaded custom rig and a standard, minimum-frills stock unit can be well over $150,000, and that money can often go a long way to support other areas of the municipal budget.

While it’s impossible to deny that some expensive features of the rig are absolutely necessary, it’s important that you don’t blow your budget on the fancy frills your apparatus doesn’t need. Budget concerns are the #1 reason why governing bodies don’t approve apparatus purchase proposals, so you have to make sure your expenses are justified when designing your rig.

Read More

Marion Body Works Unveils Innovative Rescue Pumper at FDIC 2015

FDIC has always been one of our favorite events to attend, and this year is no different. Last year, we unveiled our 50th anniversary demo Pumper and Aerial, as well as a recently delivered Rescue unit for the Sugar Creek Township Fire Department. We’re always excited to show off the new features and innovations that we’ve added to our apparatus arsenal, and this year we have something even more impressive to unveil at Booth 3247.

Read More

12 Tips for Designing the Optimal Fire Apparatus Storage Compartments

As we continue to see more and more fire departments purchasing rescue vehicles and multipurpose apparatus, there’s been a lot of discussion about how to maximize these rigs’ storage capabilities. Rescue vehicles are known for having bigger, better, and more diverse storage options than other apparatus types, and basically serve as mobile fire equipment storage lockers.

Read More

How to Determine if Your Department Needs an Initial Attack Fire Apparatus

As more and more departments start to downsize their fleet in favor of multipurpose apparatus, like our RPM, many are contemplating purchasing an initial attack vehicle. Initial attack fire apparatus come in a variety of different designs, and vary from department to department based on their intended use. While some departments use them to initiate fire suppression attacks and provide support while waiting for larger pumpers to arrive on the scene, other departments have used them to respond to smaller fires that require fewer personnel.

Read More

10 Helpful Tips for Making Winter More Bearable on Your Rig

If you think cold weather is brutal on your body, it's just as brutal on your apparatus. From freezing temperatures to corrosive ice-melting agents, there’s a lot your rig has to withstand during the winter. And if you don’t take proper steps to maintain it, these problems can cause some serious headaches and lead to costly long-term damage.

To make sure your apparatus stays in tip-top shape this winter, here are a few tips to follow:

Read More

Custom vs. Commercial Chassis – 10 Key Differences to Consider

With budgets being tight and new apparatus costing well into the six-figure range, fire departments everywhere are looking for ways to save. And when it comes to building a new fire apparatus, one way that fire departments have been able to cut costs is by using a commercial chassis. Commercial chassis can cost less than half the price of their custom counterparts, but does that really make them a better option?

If your department is trying to decide if a custom or commercial chassis makes sense for your next fire truck, here are 10 key comparisons to consider before you make a decision:

Read More

6 Tips for a Successful Final Inspection with Your Apparatus Manufacturer

After months of debating different specs, pouring over designs, and deciding what features to include on your new rig, your department’s new apparatus is finally ready for final inspection with the manufacturer. The final factory inspection is an extremely important part of the truck-building process and it shouldn’t be taken lightly. This will be the last opportunity to ensure your apparatus is built exactly to your specifications, and find any deficiencies before it’s delivered to you.

Read More

The 5 Best Features of a Rescue Pumper

There are plenty of reasons why Rescue Pumpers have evolved into an essential tool in today’s fire service. As more and more fire departments see an increase in their response area and service responsibilities, it’s the perfect multifunctional apparatus that allows departments to kill two birds with one stone. You’re able to fulfill all the water-carrying duties of a Pumper, while also having the storage capabilities and versatility of a Rescue.

Read More

Why a Rescue Pumper Has Evolved Into An Essential Tool In Today’s Fire Service

When it comes time to purchase a new apparatus for your fire department, it’s easy to get overwhelmed by all of the different options. There’s a lot you need to consider when figuring out which apparatus will be the most effective and efficient, and even the most experienced committees still struggle to decide on the best specs and features.

As the number of non-fire-related responses continues to rise, however, fire departments across the country are starting to downsize their fleets in an attempt to stay under budget. This has changed the way departments approach buying a new apparatus.

Read More

Buying an Apparatus: Five Things to Look for in a Dealer

Once you’ve gotten the approval to purchase a new fire apparatus, the next step is finding a dealer to purchase it from. As a matter of fact, you probably have a few in mind already. A new apparatus is a big investment, and you want to make sure you’re buying from the right company.

So when it comes time to choose a dealer, what are you basing your criteria on? Price and apparatus quality are the two important factors, but those aren’t the only things that affect your buying experience. To help you find a dealer that will provide the best apparatus for the best available price and the best overall buying experience, here’s a list of 5 things to look for when deciding on one:

Read More

5 Benefits of Buying a Demo Fire Apparatus

Each year, truck manufacturers all over the U.S. build demo vehicles to display at the industry’s biggest trade shows. Builders want you to experience everything they have to offer first hand, and these demo vehicles help them do just that. Like every other vehicle, these demos are built to meet the industry’s highest quality and manufacturing standards, as well as standards for performance in the field. And while these demo vehicles might not have all the exact, customized features your department is looking for, that doesn’t mean it isn’t a specialized vehicle.

Read More

5 Indicators Your Department is Ready for a New Fire Apparatus

With a new apparatus ranging anywhere in price from $100,000 to over $1,000,000, you can be sure that your department will be looking to maximize its investment and squeeze every possible hour of service out of your vehicles. That being said, when an apparatus is approaching the end of its effective life expectancy, it isn’t always easy to determine whether or not it needs to be replaced. Sure it might not perform like it did fresh off the factory room floor 10-15 years ago, but do you really need to spend all that money and go through the process of replacing it just yet? Would it be more feasible to just repair the apparatus?

Read More

9 Questions to Ask Your Department Before Buying a New Fire Apparatus

Though the thought of replacing an aging apparatus might seem exciting to most fire departments, it’s a decision that must be made after a lot of careful thinking and deliberation. With even your most basic apparatus costing well over $300,000 to build these days, buying a new apparatus is an investment your department can’t afford to take lightly. In addition to their expensive price, each apparatus must also stand up to any challenges the buyer might put it up to. Lives will literally depend on your apparatus’ reliability and functionality, so it’s important every penny spent is justified.

Read More

Apparatus Answers: How Marion Combats High Hosebed Problems

Have you ever looked at the height of the hosebed on your pumper and wondered, “Why does this have to be so tall?” If so, you’re not alone. However, with more and more customers calling for full-depth, full-height storage compartments without sacrificing tank size, sometimes the only direction to go is up. In order to make these tall hosebeds both safer and more accessible for your department, Marion has come up with an interesting solution.

Read More

6 Tips for Specifying Your Next Rescue Apparatus Purchase

A rescue apparatus can be one of the most challenging projects for an apparatus committee. Because each rescue apparatus is highly customized to fit each department’s unique needs, the committee is forced to make a number of difficult decisions regarding the apparatus’ size, additional features, storage compartments, and more.

To help your committee plan and design the perfect rescue apparatus for your department, the build team here at Marion has put together these useful tips for planning your next rescue purchase:

Read More

4 Ways to Prevent Corrosion on Your Next Fire Apparatus

For nearly 110 years, Marion Body Works has been manufacturing some of the toughest, most durable fire apparatuses on the planet. When it comes to building a tough truck that always performs under the harshest of conditions, we can certainly teach you a thing or two. In order to build an apparatus that stands up to corrosion and the long-term effects of daily use, it all starts with the materials and manufacturing techniques used during the manufacturing process.

Read More

Marion Body Works Announces Exclusive Coatings Supplier Partnership With PPG

This post originally appeared on Marion's News Section which can be found here.

This post originally appeared on Marion's News Section which can be found here.

Marion Body Works, a leading manufacturer of Fire & Emergency apparatus, Commercial truck bodies, aluminum custom cabs, custom engineered vehicles, and Defense products, announced that it has established an exclusive vendor partnership with PPG Industries. PPG will supply all coatings for Marion’s fire & emergency apparatus.

Read More

We’re Headin’ To Indy!

One of our favorite events, the FDIC (Fire Department Instructors Conference) is all set for this coming Monday, April 7, a day that kicks off a fantastic week-long show. Marion be at the show starting Thursday, April 10, on the show floor in the Indiana Convention Center.

One of our favorite events, the FDIC (Fire Department Instructors Conference) is all set for this coming Monday, April 7, a day that kicks off a fantastic week-long show. Marion be at the show starting Thursday, April 10, on the show floor in the Indiana Convention Center.

Marion Body Works Celebrates 50 Years Of Building All Aluminum Fire Apparatus

This post originally appeared on Marion's News Section which can be found here.

Marion Body Works, a leading manufacturer of Fire & Emergency apparatus, Commercial truck bodies, aluminum custom cabs, custom engineered vehicles, and Defense products, announced that it is celebrating the 50th anniversary of building all aluminum fire apparatus, longer than any fire apparatus manufacturer in the country.

Read More

Steel vs. Aluminum Fire Truck Cabs: 5 Benefits of Extruded Aluminum

“Built Ford Tough” just got a whole new meaning. This past July, the iconic American automaker made waves in the automotive industry when the company announced that its 2015 F-150 trucks would lose up too 700 lbs., thanks to a newly designed aluminum alloy engine block and frame. Though traditionally manufactured using steel, the falling price of aluminum and impending fuel economy standards made it an easy choice for Ford executives.

“Built Ford Tough” just got a whole new meaning. This past July, the iconic American automaker made waves in the automotive industry when the company announced that its 2015 F-150 trucks would lose up too 700 lbs., thanks to a newly designed aluminum alloy engine block and frame. Though traditionally manufactured using steel, the falling price of aluminum and impending fuel economy standards made it an easy choice for Ford executives.

As Motor Trend senior editor Jonny Lieberman said, “substantially lowering a vehicle’s weight increases the performance and the mileage. If the costs can be kept in check, and if repairs are reasonable, Ford has a definite winner on its hands.”

Read More

Welcome to the Fire & Emergency Blog!

We’re all very excited to unveil our redesigned website, and one feature we’re most eager to share is the addition of two blogs (click here for our Commercial Truck Bodies Blog). Our goal is to regularly update the blog with posts from experts on our Fire & Emergency team. They’re going to share the latest company and industry news, and provide helpful resources for departments looking for a new fire apparatus or other emergency vehicles. Check back often for posts on a variety of subjects, including:

We’re all very excited to unveil our redesigned website, and one feature we’re most eager to share is the addition of two blogs (click here for our Commercial Truck Bodies Blog). Our goal is to regularly update the blog with posts from experts on our Fire & Emergency team. They’re going to share the latest company and industry news, and provide helpful resources for departments looking for a new fire apparatus or other emergency vehicles. Check back often for posts on a variety of subjects, including:

Stay Connected With Marion.

Elevate your game by subscribing. We'll take care of the rest!

715.754.5261

211 W. Ramsdell Street

Marion, WI 54950-0500

©2019 Marion Body Works, Inc. | All rights reserved. Reproduction without permission is prohibited.